Corrosion Protection in highest quality for cast parts

Our coating with the EWS-procedure (Epoxy-Vortex-Sinter) is GSK approved. (Quality association for heavy duty corrosion protection)

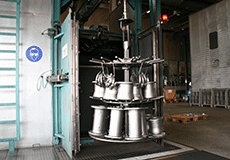

- for untreated cast parts (GJS GJL / GGG, GG)

- We blast with very hard sharp-grain

- Impact velocity: ca. 75 m/sec.

Because of the slow, continuous warming of the cast parts, we are able to heat up big as well as small parts, without overheating.

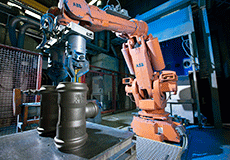

Robot supported EWS-Coating in the fluidized bed

One of the most advanced coating plant for EPOXY-coating in fluidized bed procedure, guarantees a valuable corrosion protection.

Due to the Robot handling we reach a constant quality and layer thickness. But only the people in the company can design and implement the necessary shift processes.

Coating laboratory

In our laboratory we prove the quality according to the principles of "Heavy duty corrosion protection".

Every half year we are checked by the MPA-Hannover.